Learning Center

How Monuments Are Made

How Monuments Are Made

Granite is a natural stone that is formed together when its molten substances cool and solidify slowly in the depths of the Earth. Granite comes from quarries, which are open-pit mines from which rocks or minerals are extracted.

Quarrying

To extract the granite out of the ground, it is quarried into blocks. Due to the structure and composition of granite, it is never quarried by blasting as this would fracture the granite into unusable pieces. Rather, it is carefully removed by either drilling or jet piercing. When granite is drilled, vertical holes are bored into the structure approximately one inch apart and up to depths of twenty feet. The granite that remains between the holes is later removed by secondary drilling. Jet piercing involves the use of a jet burner. This high velocity, 3,500-degree Fahrenheit flame acts as a blow torch that cuts through the granite to form channels that will eventually allow a block of the material to be removed. Blocks are usually four feet deep, four feet high and eight feet long. Once the block is lifted and free from the ground, it is ready to be transported to the manufacturing facility. Blocks of granite can weigh as much as ten tons.

Sawing

Once at the manufacturing plant, the blocks are cut into slabs of varying thickness by circular saws with industrial diamond tips. These modern saws, which can measure up to fourteen feet in diameter, are usually computer operated and high speed; which greatly increases the productivity of the manufacturing facility.

Polishing

Slabs of granite are polished by automated machines that often use either large metal discs or abrasive bricks made of silicon carbide. Polishing the granite produces a gloss finish with almost a mirror-like appearance. The polished slab of granite is then run through a guillotine that splits the slab into the desired size. The rough edges are finished and trimmed by trained craftsmen using traditional hammers and chisels. The monument may now be polished on the edges or left rough, also known as rock pitched, depending on what is required by the particular order.

Sandblasting

Virtually any designs and lettering can be sandblasted into the granite. Most often, a design that was created on a computer CAD system is used to produce a flat sheet of rubber known as a stencil. The computer-generated stencil is fabricated by using a special plotter driving a knife to create the required design. The flat sheet of rubber is placed onto the monument with a glue, or filler, and the areas of the stencil to be sandblasted are removed from the stone. The monument is then taken into a blasting room or cabinet where fine particles of abrasive are blown by compressed air against the granite. The abrasive cuts away all areas of the granite not protected by the stencil. Once complete, the stencil is removed, the monument is cleaned and it is then ready to be packaged and shipped to the local monument retailer.

Carving

Skilled carvers and sculptors create the desired design in granite by using sharp chisels powered by compressed air. These pneumatic tools allow for the creation of hand-crafted, three-dimensional designs. Carvers have the ability to add beautiful dimension to any design while sculptors can create full figures out of granite. The work of a sculptor usually reflects the highest levels of artistry and design.

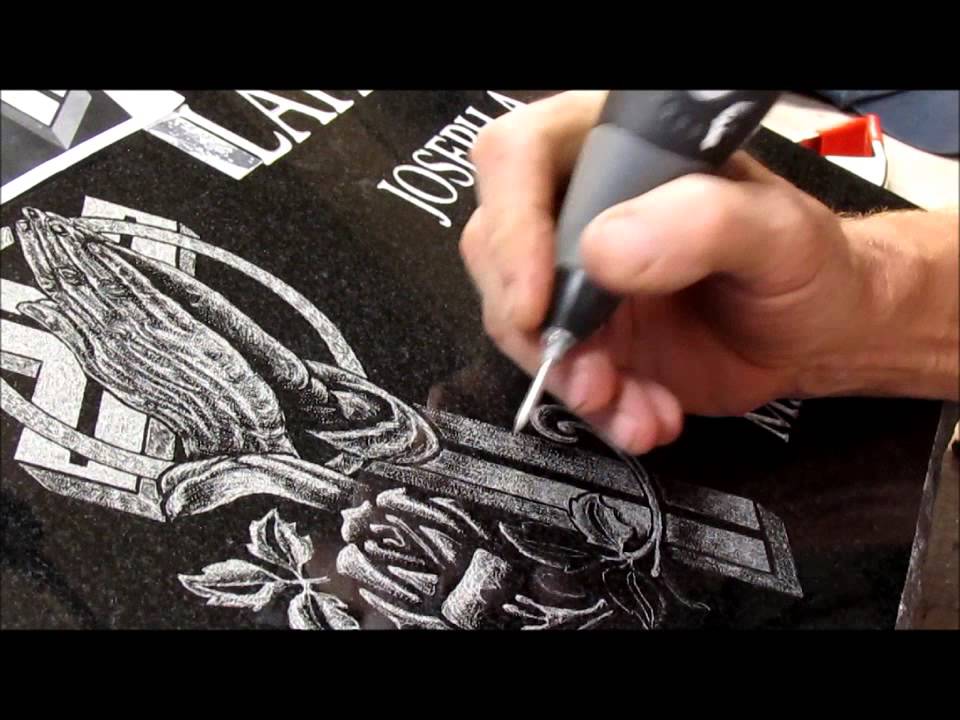

Etching

Etching is a process that uses either a handheld diamond tip etching tool or a computerized laser etching machine. An etched surface removes the polish of the stone to produce a very detailed portrait, drawing or scene. Hand etching is a specialized skill created by a true artist while laser etching utilizes a computer program to produce an exact duplicate into the polish. Most often, etchings are done only on black granite but, in some cases, can be completed on some darker granites.